Evaluating Machining Applications for Magnetic Chuck Workholding

There an assortment of components to consider while choosing the kind of attractive throw for a machining application.

As an option in contrast to mechanical clasping of work-pieces, attractive tosses are ideal for holding ferromagnetic work-sorts out. They are usually utilized in crushing, processing, sparkle disintegration and bed stacking applications.

Attractive throws comprise of a precisely focused lasting magnet face. Fixed shaft pieces are carried into contact with electromagnets or lasting magnets. The work-piece to be held shuts the attractive circle or way, onto those fixed plates, giving a safe anchor to the work-piece.

To harvest the points of interest, various variables should be considered to appropriately wed the attractive throw to the application.

Attractive Chuck Application Considerations

There an assortment of components that should be thought of, including:

Sort of Material: Magnetic hurls just work with materials that have a capacity to be polarized. Paramagnetic or diamagnetic materials don't charge well if at all and are bad possibility for attractive throw workholding. Material hardness, shape and levelness of the work-piece material are likewise important for the material assessment measure.

Sort of Machining: Machines and kind of machining are significant contemplations for the choice of an attractive toss. Factors, for example, the drive, axle speed, and size of shaper or apparatus should be thought of.

Surface Area: Magnetic holding power is straightforwardly corresponding to the surface zone. More modest parts that have less accessible contact territory may require positive stops to conquer the powers of the machine. Unpredictably formed parts may require an attractive installation to safely hold the work-piece.

Chip Control: Chips are for the most part not an issue for attractive workholding on the grounds that the toss' attractive field doesn't make chips stick to the work-piece. Notwithstanding, if chip issues happen, they can be eased by utilizing variable control alternatives to decrease the measure of power applied or by utilizing riser squares to get the attractive circuit far from the machining region. At the end of the day, the toss can be intended to restrict the profundity of the attractive field, keeping the power from maneuvering chips into the work-piece.

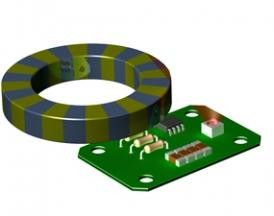

Kind of Magnet: There are three sorts of attractive circuits utilized with attractive tosses: perpetual attractive, electromagnetic and electro-lasting. Lasting attractive throws are precisely impelled through a switch and have a non-variable clipping power. Electromagnetic hurls use DC voltage in a loop encompassing gentle steel post pieces to create the attractive field; they need consistent force application. Yet, they can give variable holding power, which extraordinarily improves their capacity to help a wide scope of machining conditions. Electro-perpetual throws are a lasting/electromagnet half breed. In this plan, when DC voltage is applied to the curl that encompasses the perpetual magnet, the material is charged and gets attractive. Electro-perpetual magnets won't lose attractive fascination if there is a force misfortune, which makes them convenient.

Comments

Post a Comment