Employing Lifting Magnets For Material Handling Operations

Attractive lifters are a lightweight and practical method of shipping substantial materials in circumstances where another technique for material taking care of would be troublesome, hazardous, or costly.

These lifters use magnets to hold substantial materials safely without requiring cinches, slings and other holding gear. They are generally helpful in circumstances in which another strategy for material dealing with would be troublesome, hazardous, or costly.

Lifting magnets shift broadly in size. Normally, the bigger ones are swung from a chain on a crane that can move the lifting magnet into the area important to recover the material. This sort of lifter can be utilized for a wide assortment of purposes, including auto trashing, development, and destruction and cleanup.

How Lifting Magnets Work

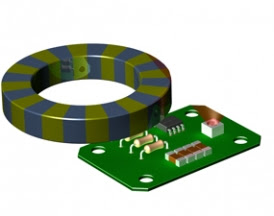

There are two kinds of lifting magnets: perpetual magnets and electromagnets. Perpetual magnets utilize for all time charged material to make an attractive field. They can be utilized to lift stacks as much as 2,200 pounds. These lifters can be moved effectively to different work areas. In any case, one weakness of perpetual magnets is that they have a limited lifting limit. In the event that a variable lifting limit is required, the ideal decision is the electromagnetic lifter.

Electromagnetic lifters utilize an empowered electrical loop twisted around a steel center to situate attractive areas inside ferrous materials a typical way, accordingly, making an attractive field. In contrast to lasting magnets, electromagnets require a steady DC power source. Henceforth, a force disappointment can be a security issue with electromagnets except if a crisis force or reinforcement supply is coordinated with this sort of lifting framework.

Perpetual magnets are supported (1) when power isn't free, (2) when power disappointments are a typical event, or (3) when customizable attractive power isn't fundamental. Electromagnets are the decision for applications where fluctuating strength or far off magnet control is required.

Appropriate Applications for Lifting Magnets

Smooth, Flat Surfaces: Permanent lifting magnets are physically worked. They make a solid yet low attractive field so they are touchy to air holes between the magnet and the heap. At the point when an air hole expands, the attractive power will be essentially decreased. They work best on smooth, level surfaces as opposed to harsh and unpredictable ones.

Sort of Material: While ferromagnetic materials are naturally charge capable, paramagnetic materials, for example, aluminum and magnesium are definitely not. (Diamagnetic materials, for example, copper, lead, and silver, don't polarize.) For materials other than iron-based materials, a decrease factor should be determined to decide the powerful holding power.

Thickness of Material: The thickness of the material to be lifted additionally assumes a job factor in choosing a lifting magnet. Thick materials are the best up-and-comers. Materials more slender than the particular for the lifting magnet will have a much lower level of holding power.

Advantages

Lifting magnets save time by decreasing and in some cases killing hindering and throwing. They can likewise take out or decline squander. They decrease item harm generally brought about by chains, snares, and other mechanical gets. In any case, the critical preferences of lifting magnets are simplicity of activity and cost-viability.

Comments

Post a Comment